Custom Tooth Clutches

The custom tooth clutches are ultra-reliable couplings used in gearbox and machine tool applications. The clutch consists of two halves: a moveable shifter side and a stationary bearing side. The two parts of the clutch work together to both engage and disengage axially. The axle can rotate or remain idle; the performance of the tooth clutch is strong in either case. A custom Tooth clutch generally has a longer lifespan than a drive shaft, ensuring utmost machine efficiency.

The custom tooth clutches are ultra-reliable couplings used in gearbox and machine tool applications. The clutch consists of two halves: a moveable shifter side and a stationary bearing side. The two parts of the clutch work together to both engage and disengage axially. The axle can rotate or remain idle; the performance of the tooth clutch is strong in either case. A custom Tooth clutch generally has a longer lifespan than a drive shaft, ensuring utmost machine efficiency.

We offer two types of customizable tooth clutches: coupling and bearing styles. The coupling tooth clutch features an internal keyway on both the stationary and shifter sides; the bearing clutch is outfitted with a keyway on the shifter and bearing on the stationary side. Both of these tooth clutch types function with a mounted shifter assembly to facilitate axial engaging and disengaging during rotation or idling.

Tooth clutches possessing at least three teeth lend strength and economy to your operation. Adding more teeth as needed allows for an earlier engagement at slower speeds. The industry-leading engineers at Dayton Superior Products are happy to assist customers with tooth clutch design ideas based on application requirements.

Hover over to show more detail of our tooth clutch.

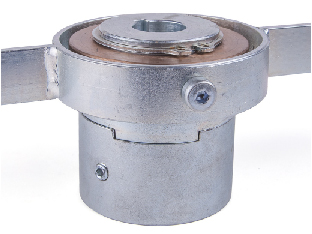

Tooth clutch - shifter side. Fully assembled clutch shown with a sliding jaw, bearing sleeve, snap ring, and shifter assembly.

Tooth clutch - stationary side. Fully assembled clutch shown with a sliding jaw, bearing sleeve, snap ring, shifter assembly, and engaged stationary coupling.

Stationary Clutch Part

Custom Tooth Clutches

Dayton Superior Products, a supplier of clutches, shaft collars, and other power transmission components, offers customization of tooth clutches to comply with exacting application requirements. We work in partnership with small business owners and Fortune 500 companies alike. We offer solutions, services and support on all of our products. Contact us today for a price quote or to learn more about our catalog of products.

Notes:

Coupling (C) Type has an internal keyway. Bearing (B) Type has oil impregnated bearing. Shifter assembly can be mounted on either type clutch for a small additional charge. Stationary side length can be increased as needed. Standard clutch has 3 teeth spaced 60º apart.

P/N EXAMPLES

Size: 1153-1.5

Type: C

No. Teeth: 3

Tooth Form: S

Bore Size: 3/4B

SHIFTER ARM

1153-1.5 x 6 x 6

Upper Extension (Actuating) 6

Lower Exstention (Pivot) 6

For Shifter with holes 6 & 6 from C shaft

Product Details(*13.5 Mb download)

| Size | Outside Diameter | Std. Bore Shaft Diameter | Max. Bore Shaft Diameter | Std. No. of Teeth | Tooth Depth | Tooth Width | Clutch Length Open | Sifter or Stationary Length | Std. Throw | T Tapped Holes (Stationary Side) | C Diameter Bolt Circle (Stationary Side) | Actuating Arm Bolt Hole Size |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.000 | 1/2 | 1/2 | 3 | .080 | .125 | 1.350 | .625 | .100 | #4 | .880 | .281 |

| 1.5 | 1.500 | 3/4 | 3/4 | 3 | .080 | .175 | 1.850 | .875 | .100 | #6 | 1.220 | .281 |

| 2 | 2.000 | 1 | 1 | 3 | .080 | .250 | 2.600 | 1.250 | .100 | #8 | 1.690 | .281 |

| 3 | 3.000 | 1-1/2 | 1-1/2 | 3 | .180 | .375 | 3.600 | 1.750 | .100 | #10 | 2.540 | .406 |

| 4 | 4.000 | 2 | 2-1/4 | 3 | .200 | .438 | 5.250 | 2.500 | .250 | 1/4 | 3.500 | .406 |

| 6 | 6.000 | 3 | 3-1/2 | 3 | .200 | .625 | 7.250 | 3.500 | .250 | 3/8 | 5.250 | .656 |

| Size | Outside Diameter | Std. Bore Shaft Diameter | Max. Bore Shaft Diameter | Std. No. of Teeth | Tooth Depth | Tooth Width | Clutch Length Open | Sifter or Stationary Length | Std. Throw | T Tapped Holes (Stationary Side) | C Diameter Bolt Circle (Stationary Side) | Actuating Arm Bolt Hole Size |